In your search for the proper actuator, you might be wondering what duty cycle is and how it affects your application. When selecting an actuator, the duty cycle becomes important when you risk running the actuator beyond its expected operation.

We have a wide range of electric linear actuators for any application – click to browse!

What is an Actuator and Duty Cycle?

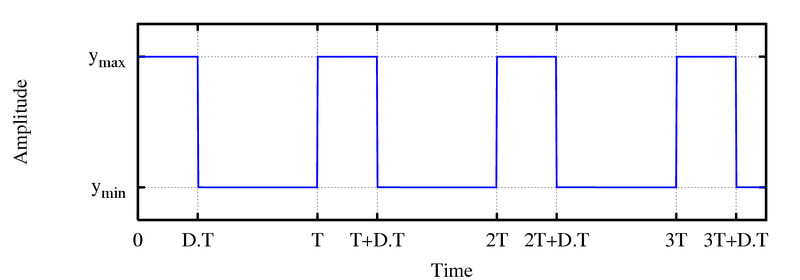

Duty cycle is the ratio of on-time to off-time, usually expressed as a percentage. This means if your actuator extends and retracts for 20 seconds, and then spends another 40 seconds at rest before the process repeats, the duty cycle would be expressed as 33%. The percentage displayed is always the ‘on’ time of the actuator. To get the off time, subtract the ‘on’ percentage from 100. In this case, you get 67%.Duty cycle is an easy calculation:

D is duty cycle

X is the amount of time the component is running.

Y is the total amount of time it takes for the actuator to complete one cycle.

If our actuator extends for 97 seconds, retracts for 45 seconds and finally rests for 79 seconds, the equation would look like:

Duty cycle becomes 64%. ‘On’ time is 64% and ‘off’ time is 36%.

Why Duty Cycle Matters

Linear actuators, like any high-running device, give off unused energy in the form of heat. If this heat becomes too much, the components will get damaged. The amount of allowable heat is determined by the component that has the lowest allowable temperature. This is commonly the motor but can be the gears in some automated linear systems. The duty cycle is set with this temperature in order to ensure the actuator does not overheat.Calculating a duty cycle works when a project or application runs at a consistent pace during the entire operation. For operations that have infrequent or erratic actuation, using this equation as a definitive answer does not always provide an accurate reading of the duty cycle. In a case such as this, it is best to calculate the duty cycle when it will be at its highest. If your actuator spends three minutes running a duty cycle of 15%, you can safely assume all other motion will run lower than this number.

Lowering the Duty Cycle

If the duty cycle is running at its highest level for that force and speed, the only way to increase the duty cycle (assuming it’s not at the maximum allowable limit for the actuator), is to reduce the load, the speed or both. Conversely, duty cycle can be decreased by increasing the load and speed.